Insight

7/4/25

How Laser Cutting is Redefining Precision in Sheet-Metal Fabrication

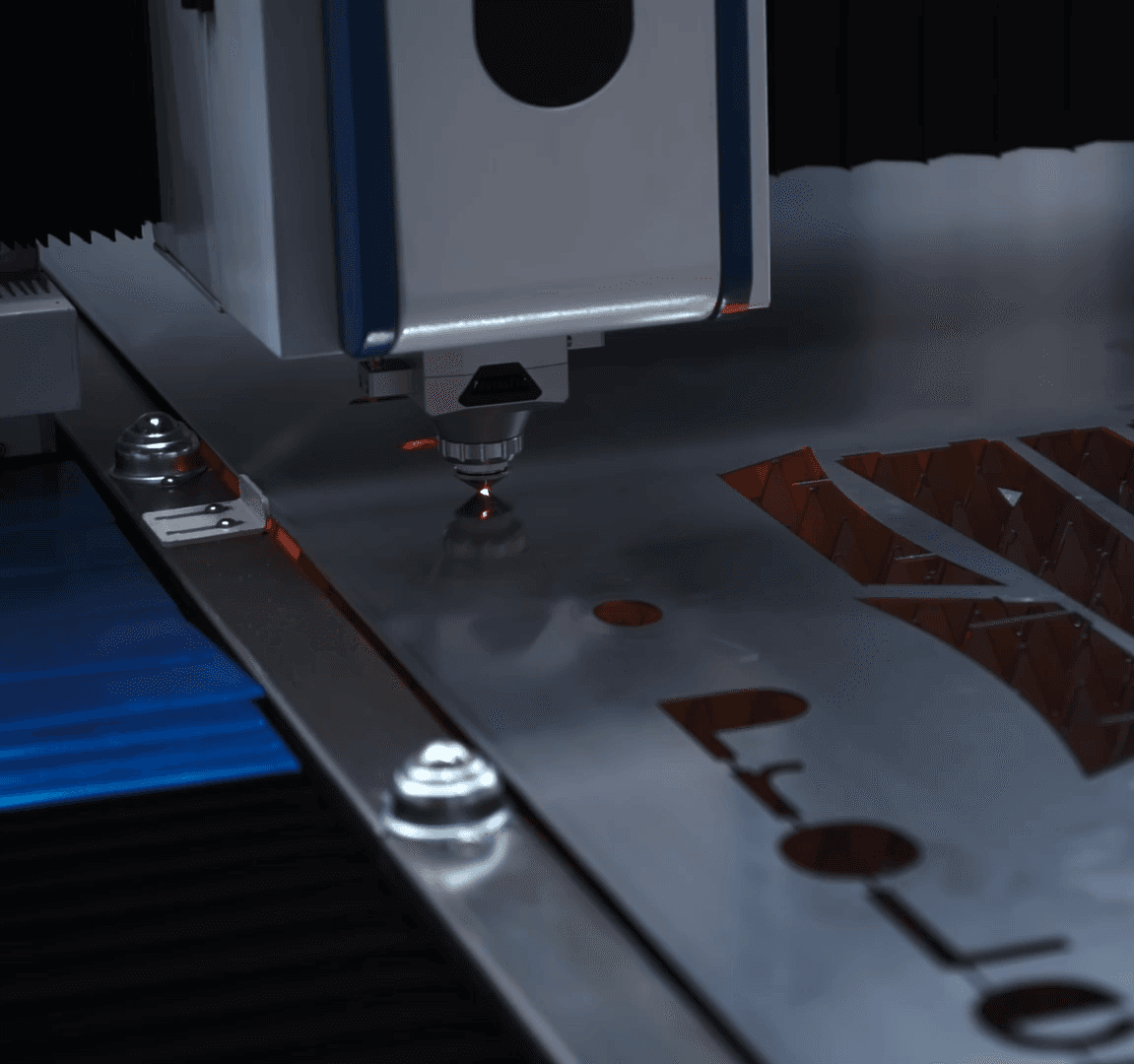

Sheet-metal fabrication has always been the backbone of OEM manufacturing. But in recent years, one technology has set a new standard for accuracy, speed, and scalability: laser cutting. From prototypes to high-volume runs, laser cutting allows manufacturers like Excava to deliver precision parts that meet strict global standards while cutting costs and reducing waste.

The Shift From Traditional Cutting Methods

Traditional cutting processes such as shearing, mechanical punching, or plasma cutting have served the industry for decades. However, as part designs have grown more complex and tolerances tighter, OEMs have demanded fabrication methods that can match modern requirements.

Laser cutting provides several advantages over conventional approaches:

Superior Accuracy: Achieving tolerances within fractions of a millimeter.

Complex Geometries: Easily handling intricate shapes and fine details.

Clean Edges: Reducing or eliminating secondary finishing.

Material Flexibility: Cutting steel, stainless steel, and aluminum with equal efficiency.

For OEMs, this means faster turnaround, fewer errors, and a clear competitive advantage.

Excava’s Laser Cutting Capabilities

At Excava, laser cutting isn’t just another step in the process — it’s the foundation of precision fabrication. Our systems are designed to meet both prototype and large-scale production needs.

Material Versatility: Cutting sheet thicknesses ranging from thin gauge to 20mm steel plates.

Repeatability: Consistency across thousands of parts ensures scalable production without deviation.

Integration: Laser cutting is seamlessly connected with our CNC bending, turret punching, and welding workflows.

Efficiency: Automated systems reduce setup time and maximize throughput for OEM supply chains.

By investing in advanced laser cutting, we help OEMs achieve higher design freedom while keeping costs predictable.

The Benefits for OEM Supply Chains

Speed to Market: Faster cutting cycles accelerate prototyping and production timelines.

Reduced Waste: Precision cutting maximizes material utilization, lowering input costs.

Scalability: OEMs can move from small batches to mass production without losing quality.

Compliance: Laser cutting supports ISO-certified processes and strict industry specifications.

Durability: Clean, accurate cuts improve the performance and fit of assembled components.

Laser Cutting in Action: Supporting Diverse Industries

Excava’s laser cutting services support industries ranging from construction and energy to defense and heavy equipment. Whether it’s complex brackets, canopy panels, or structural components, our cutting process ensures that OEMs receive parts that perform in the most demanding environments.

The Bottom Line

Laser cutting has redefined what OEMs can expect from sheet-metal fabrication. By combining speed, accuracy, and versatility, it empowers manufacturers to reduce risk and improve efficiency at every stage of production. At Excava, laser cutting is more than a capability — it’s a commitment to delivering precision without compromise.