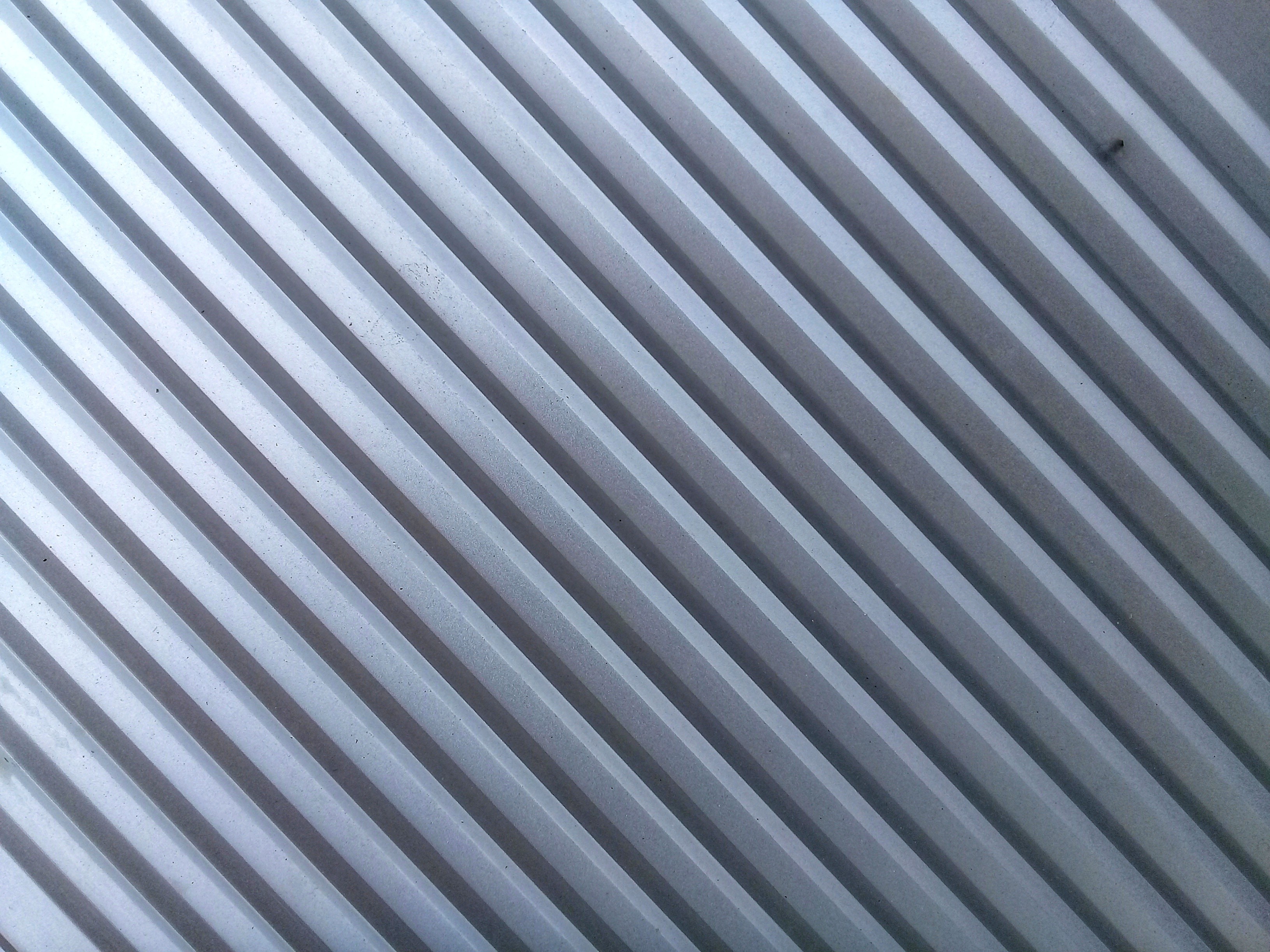

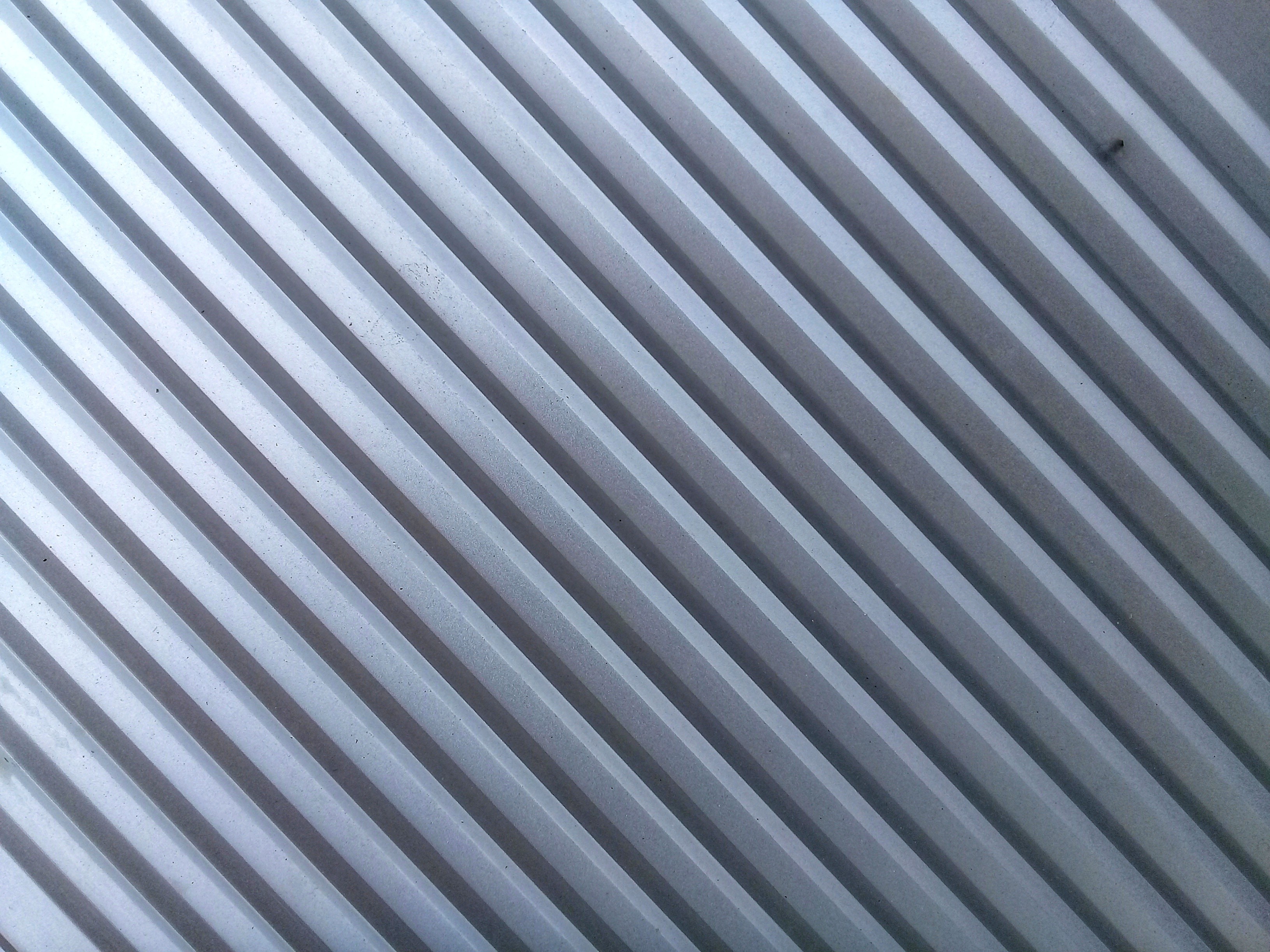

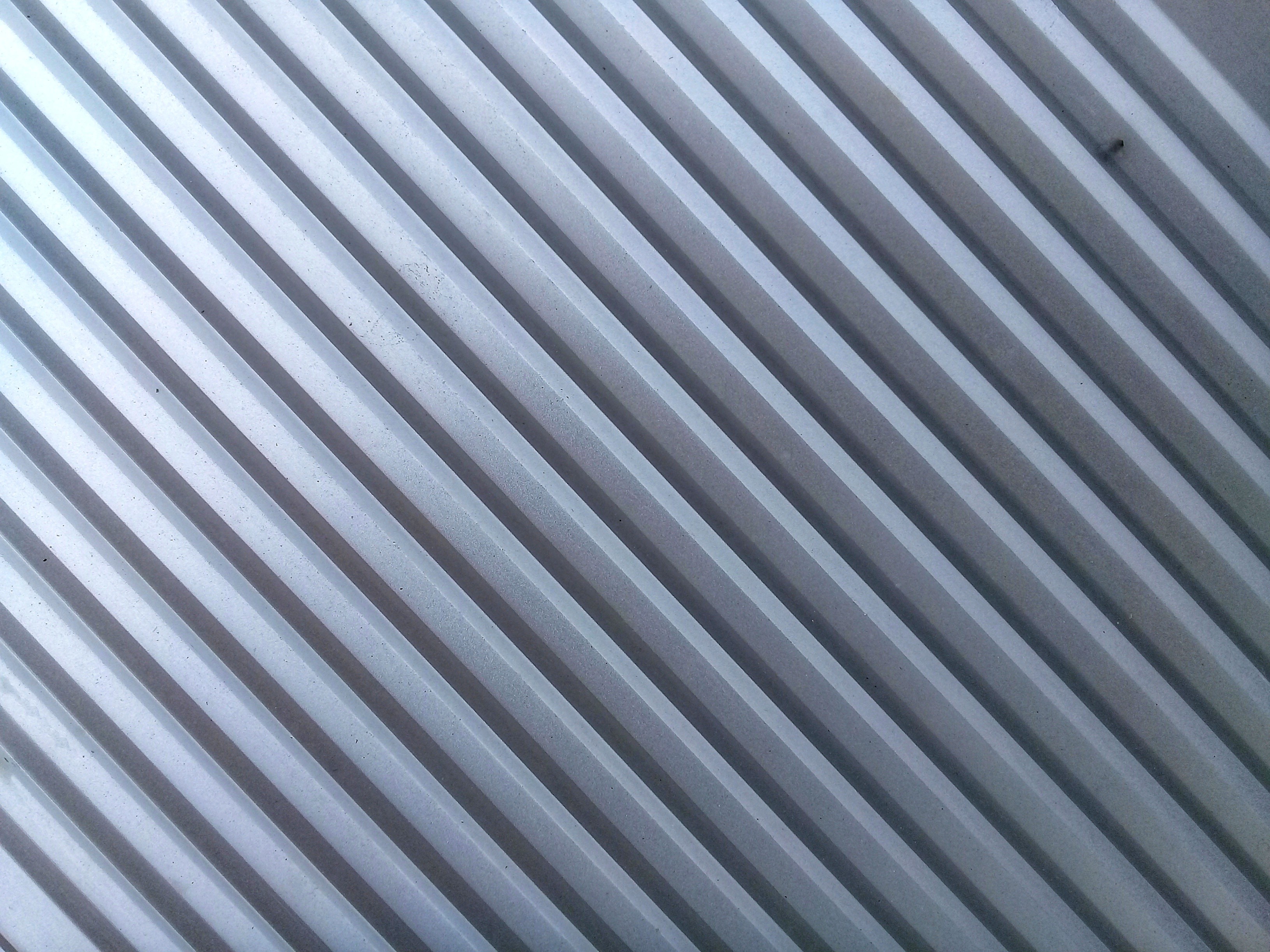

Engineering Precision in Sheet Metal Fabrication

Excava combines advanced technology with manufacturing discipline to deliver sheet metal solutions trusted by leading OEMs.

[

what we do

]

[

what we do

]

[

what we do

]

End-to-End Fabrication Capabilities

Prototyping

Our prototyping services help validate product design, materials, and manufacturing feasibility. We work with client drawings or samples, creating accurate prototypes that undergo testing and client validation, ensuring a smooth transition into scalable production with minimized errors.

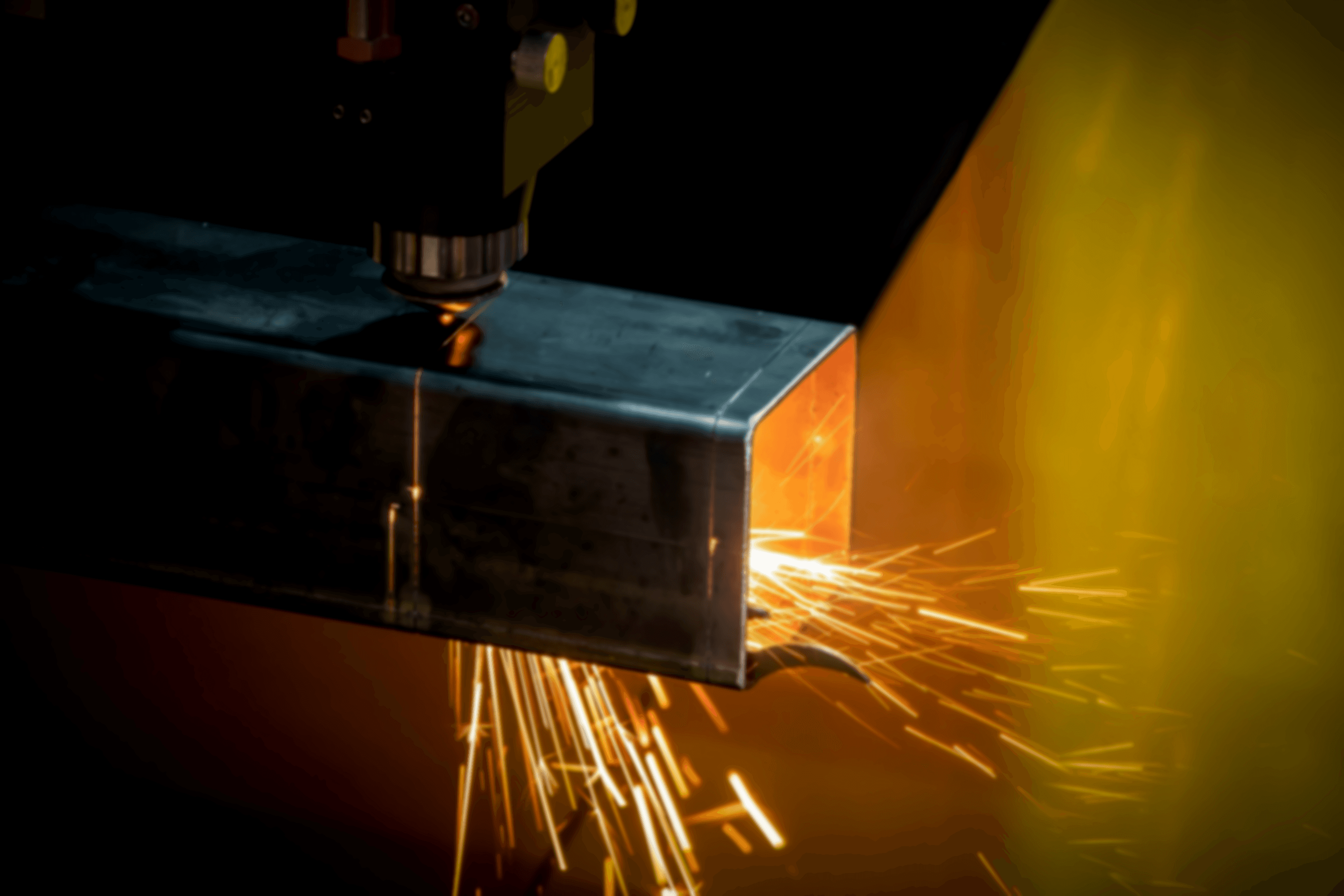

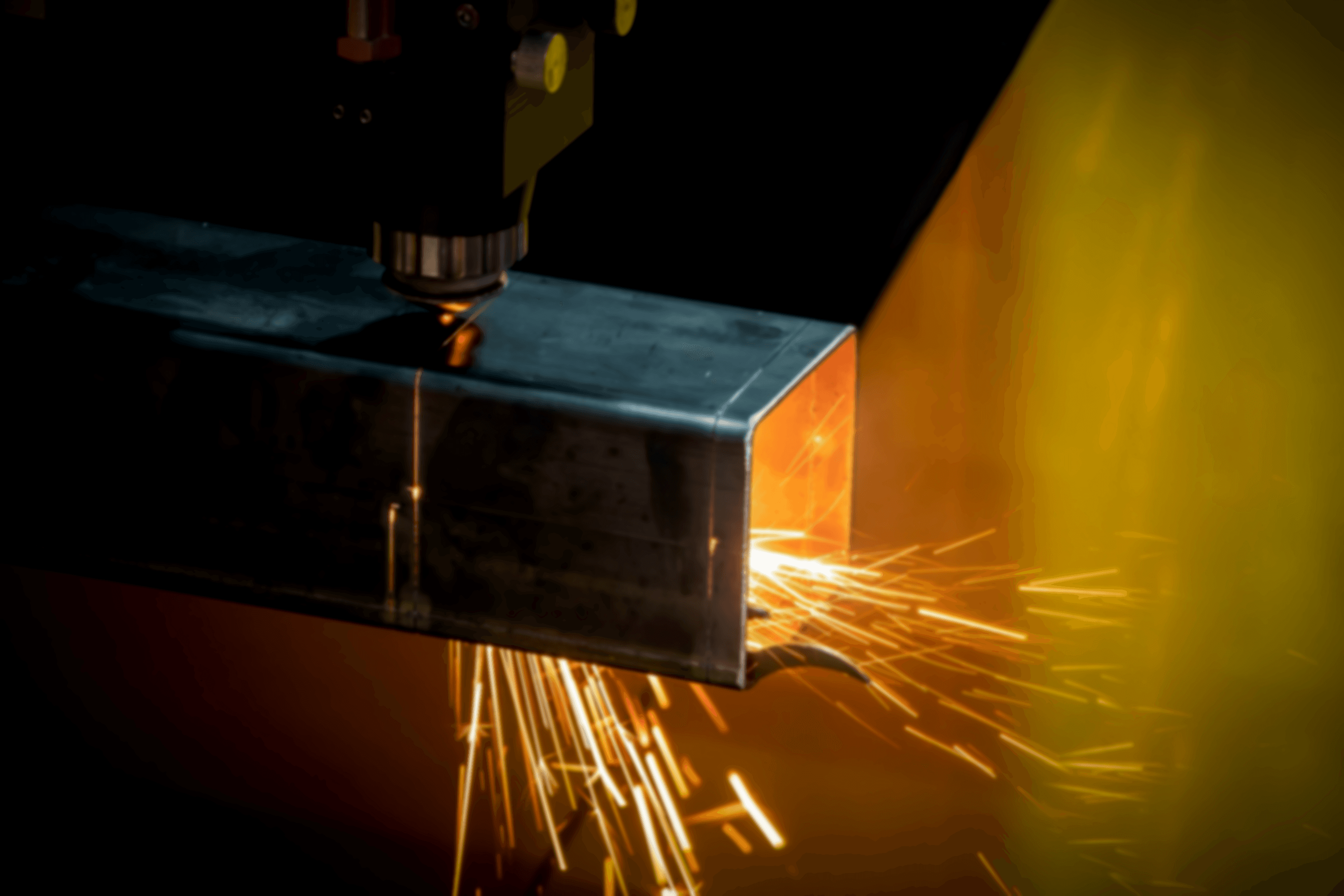

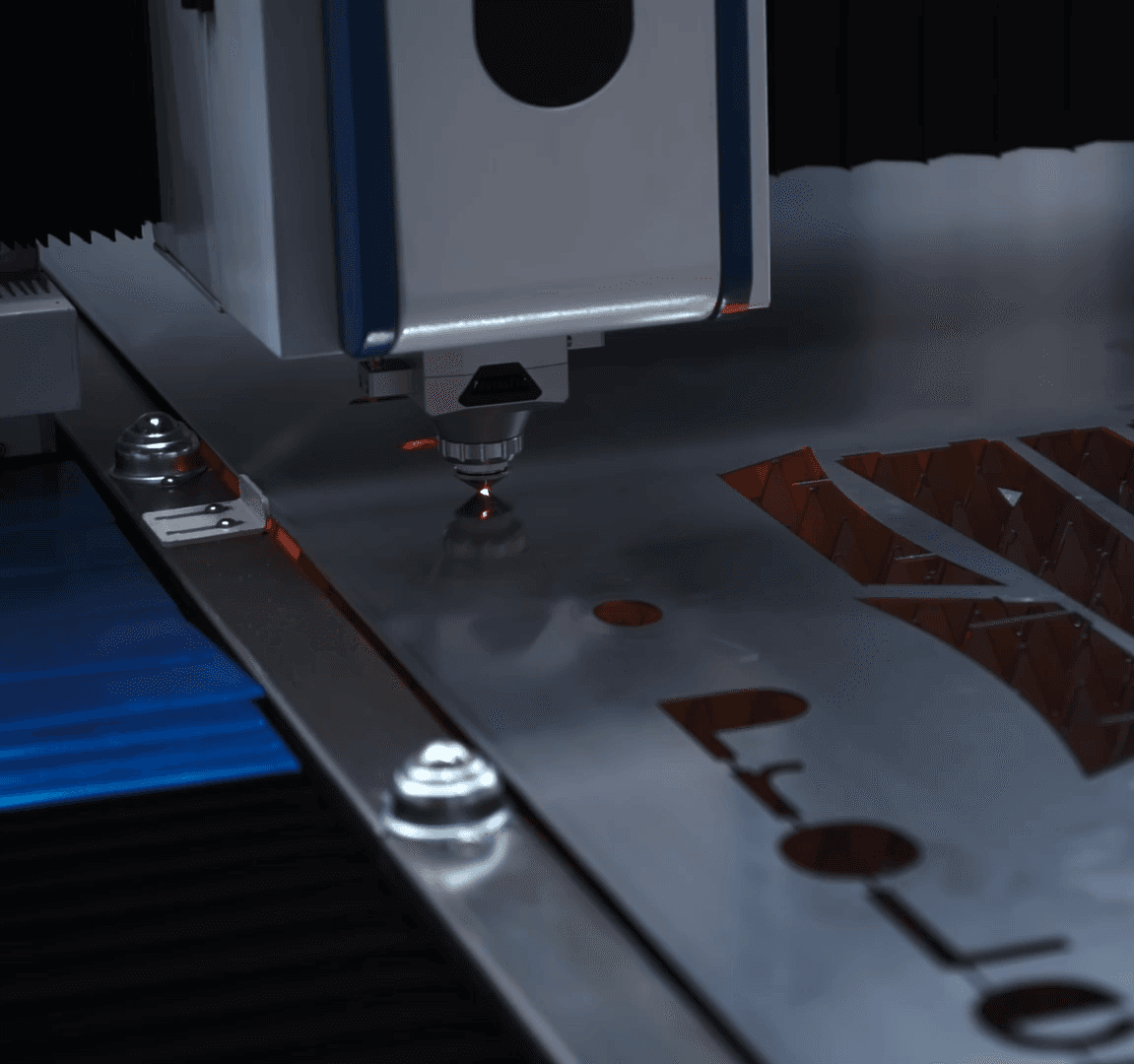

Laser-Cutting

Excava’s advanced laser cutting technology delivers high-precision profiles on sheet metals up to 20mm thickness. With clean edges, consistent repeatability, and minimal waste, our cutting process supports complex geometries and ensures accuracy for both small-batch prototypes and high-volume runs.

Bending

Using CNC-controlled press brakes, we achieve consistent bending accuracy across light, medium, and heavy sheet metal. Our process allows for complex shapes, repeatability, and tight tolerances, supporting both prototype flexibility and mass production efficiency for diverse OEM applications.

Turret Punching

Our turret punching systems enable efficient sheet metal processing for high-volume production. Capable of punching complex hole patterns with precision and speed, this process ensures uniformity, reduces setup times, and supports scalable manufacturing of components for industrial and OEM use.

Welding & Assembly

Excava provides MIG/MAG welding and precise component assembly tailored for durability and strength. Our team ensures zero-defect welds with strict quality checks, producing reliable structures and assemblies that meet global OEM standards for performance, endurance, and compliance.

Conveyorized Powder Coating

Excava’s conveyorized powder coating line ensures uniform surface finishing with high corrosion resistance and durability. Designed for continuous operations, it supports large-scale production, delivering consistent coating thickness and long service life for components across industrial and OEM applications.

Prototyping

Our prototyping services help validate product design, materials, and manufacturing feasibility. We work with client drawings or samples, creating accurate prototypes that undergo testing and client validation, ensuring a smooth transition into scalable production with minimized errors.

Laser-Cutting

Excava’s advanced laser cutting technology delivers high-precision profiles on sheet metals up to 20mm thickness. With clean edges, consistent repeatability, and minimal waste, our cutting process supports complex geometries and ensures accuracy for both small-batch prototypes and high-volume runs.

Bending

Using CNC-controlled press brakes, we achieve consistent bending accuracy across light, medium, and heavy sheet metal. Our process allows for complex shapes, repeatability, and tight tolerances, supporting both prototype flexibility and mass production efficiency for diverse OEM applications.

Turret Punching

Our turret punching systems enable efficient sheet metal processing for high-volume production. Capable of punching complex hole patterns with precision and speed, this process ensures uniformity, reduces setup times, and supports scalable manufacturing of components for industrial and OEM use.

Welding & Assembly

Excava provides MIG/MAG welding and precise component assembly tailored for durability and strength. Our team ensures zero-defect welds with strict quality checks, producing reliable structures and assemblies that meet global OEM standards for performance, endurance, and compliance.

Conveyorized Powder Coating

Excava’s conveyorized powder coating line ensures uniform surface finishing with high corrosion resistance and durability. Designed for continuous operations, it supports large-scale production, delivering consistent coating thickness and long service life for components across industrial and OEM applications.

Prototyping

Our prototyping services help validate product design, materials, and manufacturing feasibility. We work with client drawings or samples, creating accurate prototypes that undergo testing and client validation, ensuring a smooth transition into scalable production with minimized errors.

Laser-Cutting

Excava’s advanced laser cutting technology delivers high-precision profiles on sheet metals up to 20mm thickness. With clean edges, consistent repeatability, and minimal waste, our cutting process supports complex geometries and ensures accuracy for both small-batch prototypes and high-volume runs.

Bending

Using CNC-controlled press brakes, we achieve consistent bending accuracy across light, medium, and heavy sheet metal. Our process allows for complex shapes, repeatability, and tight tolerances, supporting both prototype flexibility and mass production efficiency for diverse OEM applications.

Turret Punching

Our turret punching systems enable efficient sheet metal processing for high-volume production. Capable of punching complex hole patterns with precision and speed, this process ensures uniformity, reduces setup times, and supports scalable manufacturing of components for industrial and OEM use.

Welding & Assembly

Excava provides MIG/MAG welding and precise component assembly tailored for durability and strength. Our team ensures zero-defect welds with strict quality checks, producing reliable structures and assemblies that meet global OEM standards for performance, endurance, and compliance.

Conveyorized Powder Coating

Excava’s conveyorized powder coating line ensures uniform surface finishing with high corrosion resistance and durability. Designed for continuous operations, it supports large-scale production, delivering consistent coating thickness and long service life for components across industrial and OEM applications.

[

Trusted Engineering

]

[

Trusted Engineering

]

[

Trusted Engineering

]

Building Zero-Defect Components with Global Compliance and Traceability.

[

EXCAVA SOLUTIONS

]

[

EXCAVA SOLUTIONS

]

[

EXCAVA SOLUTIONS

]

Precision You Can Trust.

Performance You Can Measure.

Full traceability and certified quality at every stage.

Full traceability and certified quality at every stage.

Full traceability and certified quality at every stage.

Robotic welding and assembly for consistency and strength.

Robotic welding and assembly for consistency and strength.

Robotic welding and assembly for consistency and strength.

Advanced laser cutting and CNC bending for complex geometries.

Advanced laser cutting and CNC bending for complex geometries.

Advanced laser cutting and CNC bending for complex geometries.

Traceability

Traceability

accelerated fulfillment

Scalability

Scalability

Scalability

[

success stories

]

Reviews from Our Customers

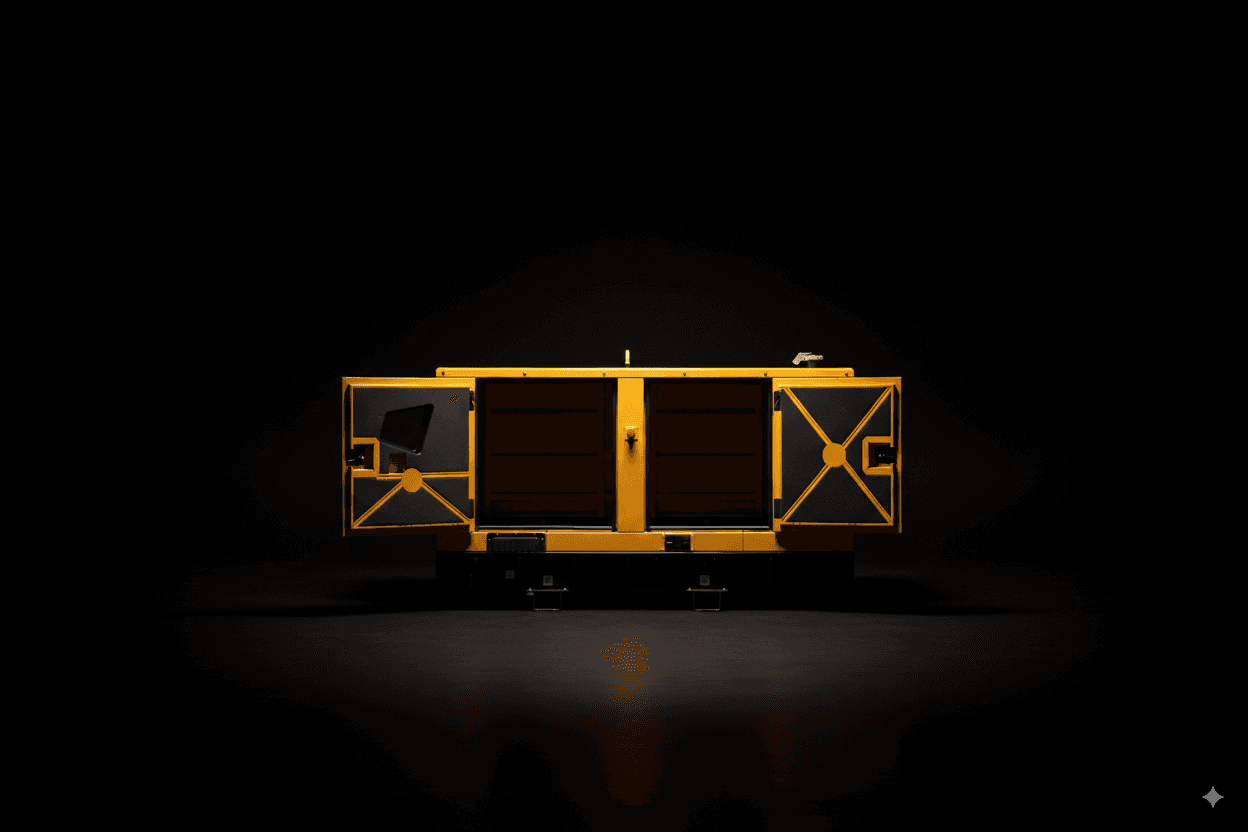

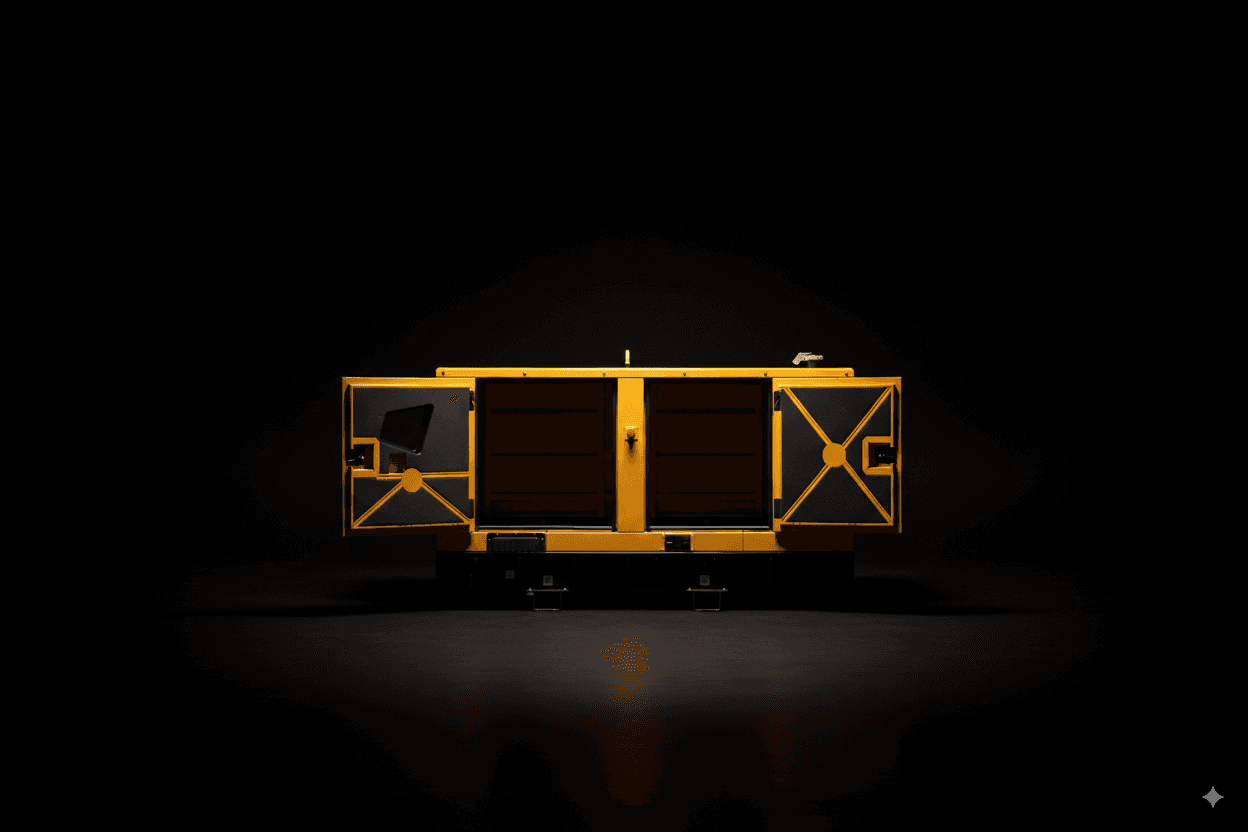

"Excava transformed our ROBOX and HOOD CLOE designs into production-ready export canopies in record time. Their agility, technical expertise, and reliable execution have made them an invaluable partner in scaling our global offerings."

Head of Product

"Excava has consistently delivered precision, durability, and first-time-right execution in developing our genset canopies. Their on-time delivery and scalable production have reinforced our confidence in partnering with them."

JCB Global Procurement Team

“ACE needed excavator buckets that could withstand extreme site conditions without frequent wear and downtime. Excava solved this by delivering abrasion-resistant, precision-engineered buckets with durable finishes. Their reliable quality and on-time deliveries have reduced our maintenance challenges and improved overall fleet performance.”

ACE Procurement & Engineering Team

[

success stories

]

Reviews from Our Customers

"Excava transformed our ROBOX and HOOD CLOE designs into production-ready export canopies in record time. Their agility, technical expertise, and reliable execution have made them an invaluable partner in scaling our global offerings."

Head of Product

"Excava has consistently delivered precision, durability, and first-time-right execution in developing our genset canopies. Their on-time delivery and scalable production have reinforced our confidence in partnering with them."

JCB Global Procurement Team

“ACE needed excavator buckets that could withstand extreme site conditions without frequent wear and downtime. Excava solved this by delivering abrasion-resistant, precision-engineered buckets with durable finishes. Their reliable quality and on-time deliveries have reduced our maintenance challenges and improved overall fleet performance.”

ACE Procurement & Engineering Team

[

success stories

]

Reviews from Our Customers

"Excava transformed our ROBOX and HOOD CLOE designs into production-ready export canopies in record time. Their agility, technical expertise, and reliable execution have made them an invaluable partner in scaling our global offerings."

Head of Product

"Excava has consistently delivered precision, durability, and first-time-right execution in developing our genset canopies. Their on-time delivery and scalable production have reinforced our confidence in partnering with them."

JCB Global Procurement Team

“ACE needed excavator buckets that could withstand extreme site conditions without frequent wear and downtime. Excava solved this by delivering abrasion-resistant, precision-engineered buckets with durable finishes. Their reliable quality and on-time deliveries have reduced our maintenance challenges and improved overall fleet performance.”

ACE Procurement & Engineering Team